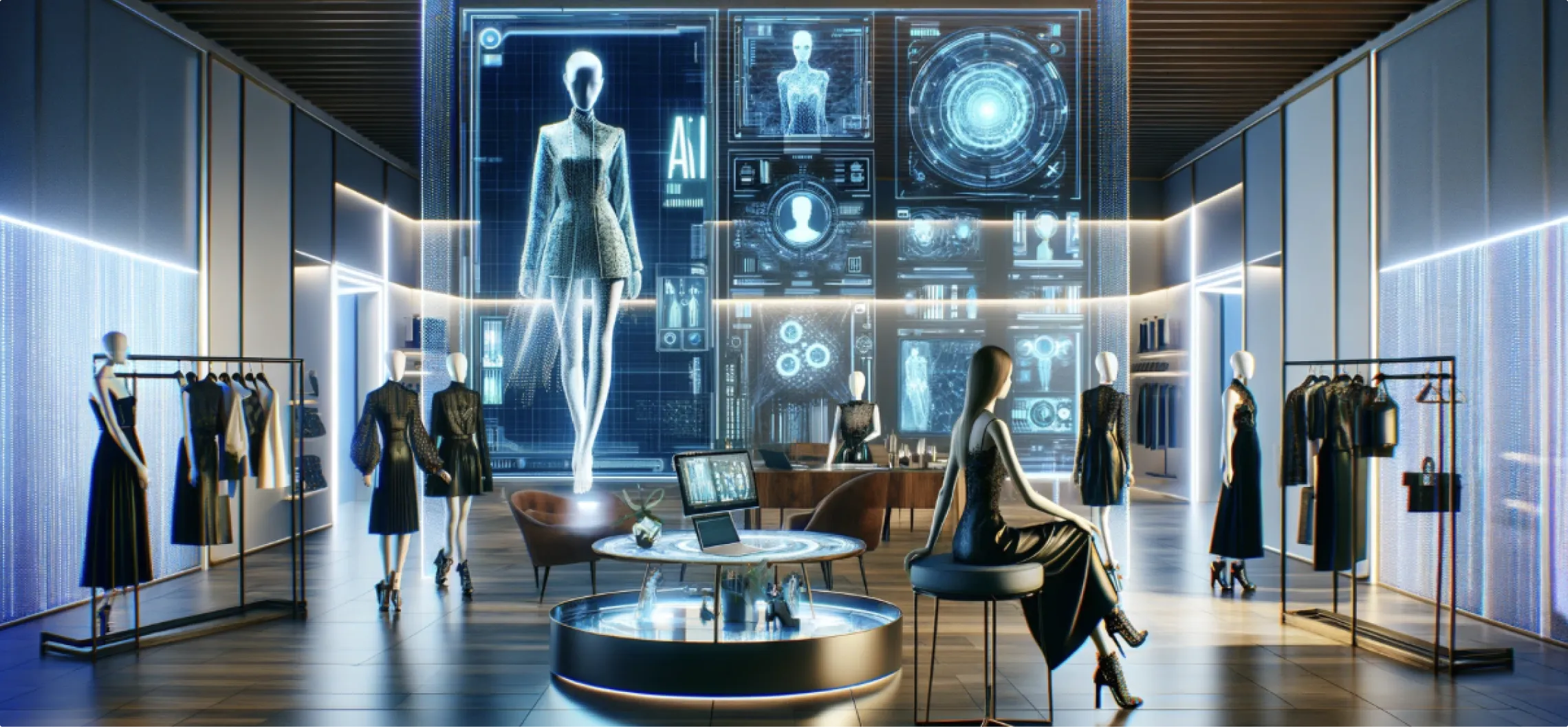

Reducing Operational Friction with Custom AI Integrations

Every morning, seasoned executives across industries face the same frustrating reality: operational bottlenecks that drain resources, delay decisions, and erode competitive advantage. While traditional automation promised relief, it often created new silos and rigid processes that couldn't adapt to real-world complexities.

Custom AI integrations represent a fundamental shift in how enterprises address operational friction. Unlike generic solutions, these tailored systems understand your unique challenges, learn from your data patterns, and evolve with your business needs. The result? Operations that flow seamlessly, decisions that happen faster, and teams that focus on strategy rather than firefighting.

The Hidden Cost of Operational Friction

Most business leaders underestimate the true impact of operational inefficiencies. Beyond obvious delays and rework, friction creates cascading effects throughout organizations. Teams spend countless hours on manual processes that should be automated. Decision-makers wait for reports that arrive too late to influence outcomes. Quality issues emerge because human oversight can't scale with production demands.

Consider a typical manufacturing scenario: production managers juggle multiple systems to track inventory, monitor equipment health, and coordinate with suppliers. Each system operates independently, forcing manual data reconciliation and creating delays in critical decisions. When equipment fails unexpectedly, the ripple effects touch everything from production schedules to customer deliveries.

INK IN CAPS has witnessed these challenges firsthand while working with Mumbai's dynamic business ecosystem. Manufacturing clients often struggle with fragmented systems that prevent real-time visibility into operations. Service companies battle with manual processes that scale poorly as they grow. Each inefficiency represents missed opportunities and competitive disadvantage.

How Custom AI Transforms Operational Reality

Process Automation Beyond Basic Rules

Traditional automation follows rigid if-then logic that breaks down when facing exceptions or contextual decisions. Custom AI systems think differently. They analyze patterns, understand context, and make nuanced judgments that mirror human reasoning but at machine speed.

Manufacturing leaders report dynamic decision-making capabilities that handle exception management and contextual judgments, reducing human intervention in routine operational decisions by significant margins. These systems don't just follow rules; they adapt to changing conditions and learn from outcomes.

Supply chain operations benefit tremendously from AI-driven demand forecasting and logistics optimization. Companies achieve substantial inventory cost reductions by accurately predicting demand patterns and optimizing stock levels across multiple locations. The AI considers factors human planners might miss: seasonal variations, regional preferences, supplier reliability, and even weather patterns.

Document processing revolutionizes knowledge work across industries. Financial institutions process contracts exponentially faster using AI document review systems, freeing legal and compliance teams for strategic analysis. The AI doesn't just extract data; it understands context, identifies risks, and flags inconsistencies that manual reviews might miss.

Predictive Maintenance: From Reactive to Proactive

Equipment failures cost enterprises millions in unplanned downtime, emergency repairs, and disrupted operations. Real-time equipment monitoring powered by custom AI cuts unplanned downtime dramatically in industrial settings. These systems don't wait for failures; they predict them with remarkable accuracy.

Maintenance cost reductions occur through failure prediction accuracy rates exceeding industry benchmarks. AI analyzes vibration patterns, temperature fluctuations, power consumption, and dozens of other variables to identify emerging issues weeks before human technicians would notice them. Maintenance teams shift from emergency response to planned interventions.

Data-Driven Insights That Actually Drive Action

Most organizations drown in data but starve for actionable insights. Custom AI analytics identify hidden workflow bottlenecks that traditional reporting misses. These systems map the entire operational flow, identify constraint points, and suggest optimizations that enable faster process cycle times.

Manufacturing quality control transforms through computer vision systems that detect defects human inspectors might miss. These AI systems work continuously without fatigue, maintaining consistent quality standards while improving detection rates substantially. They learn from each inspection, becoming more accurate over time.

Strategic Implementation for Lasting Success

Process mapping forms the foundation of successful AI integration. Smart organizations visualize their workflows to identify automation candidates and integration points before deployment. This prevents the common mistake of automating broken processes.

Data quality protocols ensure success from day one. Custom AI systems require accurate, structured inputs to deliver reliable outputs. Implementing robust data governance creates the foundation for AI models that continuously improve rather than accumulate errors.

Phased integration minimizes risk while building organizational confidence. Leading companies start with non-critical processes like inventory tracking, then progress to mission-critical systems such as production line controls. This approach maintains human oversight loops for complex decision validation while building expertise gradually.

The Competitive Advantage of Proprietary Intelligence

Leading enterprises report return on investment periods of 18-24 months for custom AI implementations, with ongoing efficiency gains compounding annually. The strategic advantage lies in developing proprietary AI models that continuously adapt to organizational needs, unlike static off-the-shelf solutions.

Custom AI integrations create sustainable competitive differentiation because they embody your unique operational knowledge and adapt to your specific challenges. Competitors can't simply purchase the same solution because your AI understands your processes, your data patterns, and your strategic objectives.

INK IN CAPS helps Mumbai-based enterprises navigate this transformation by combining technical expertise with deep understanding of local business dynamics. Their approach focuses on creating authentic operational improvements rather than impressive demonstrations that don't translate to real value.

By addressing operational friction at its source through tailored intelligence, businesses achieve more than efficiency gains. They build adaptive capabilities that respond to changing market conditions, evolving customer needs, and emerging competitive threats. Custom AI integrations don't just optimize current operations; they create the foundation for future growth and innovation.

Contact Us Now:

.CNhas5IL_ZqBJiz.webp)